Honey Extraction in words and pictures

Demonstration by David Shale and Val Bone at the Bee Shed, 12th August 2023

The whole process can be divided up into discrete operations.

Removing the honey frames

There are many gadgets to clear bees from the frames of capped honey, but all of them require more than one visit to the apiary. David favours the ‘one visit’ approach of shake and brush.

Put the bee-free frames in a box or bin with a lid as you work through the super(s). This is easier with two people. If you intend to make cut comb be sure not to damage the cappings e.g. use wide spacers while transporting the frames.

Tip: use a plastic tray underneath while transporting honey frames!

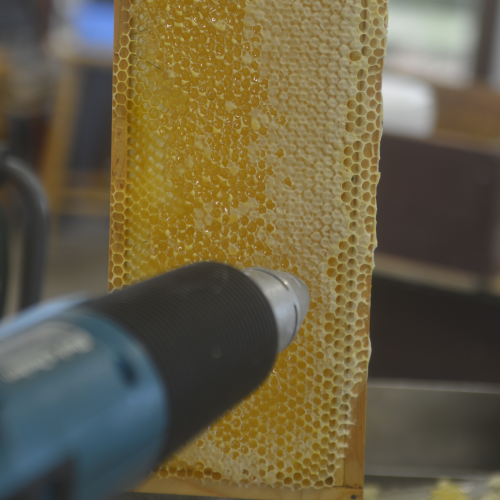

Removing the cappings

This may be achieved with the aid of a serrated knife using a sawing action (see photos). Whether you cut up (towards the fingers) or down (safer), tilt the frame slightly so that the cappings fall off.

There are many ways of doing this operation, some simple and inexpensive such as an old bread knife and baking tray, some more expensive using heated knives and trays from bee equipment suppliers. The illustration is of a Pratley heated tray. The hot air gun technique will only work when there is an air gap between honey and wax cappings (and is very messy).

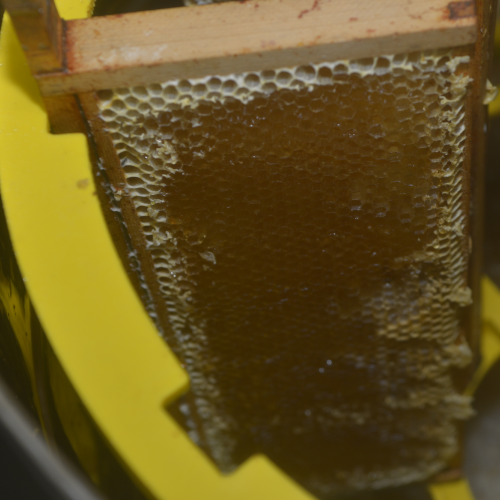

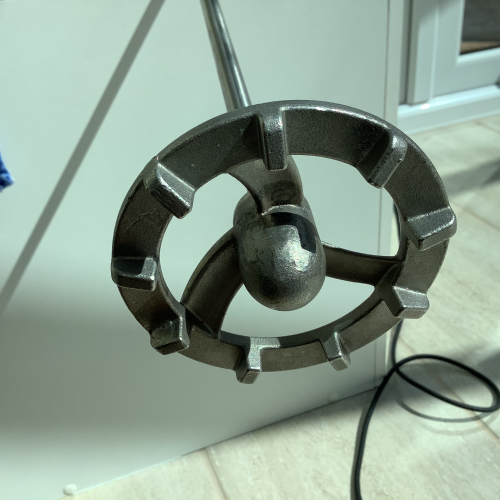

Honey Spinners/Extractors

A simple way to separate liquid honey from the frames by centrifugal force.

Two basic types:

Radial, both sides of the comb spun out in one operation.

Tangential, one side of the comb spun out at a time. Frames need to be turned round to spin the other side.

The illustrations explain the process.

Tip: Balance the full combs as well as possible. Start spinning slowly to avoid breaking the comb (especially tangential spinners). Frames in tangential spinners may need to be turned a second time and spun at higher speed to complete the extraction.

Tip: Ideally, all honey processing should be done in a warm, bee proof area. Equipment may be cleaned with water no more than hand heat (hot water will melt wax and propolis). Detergents are not needed. Dry all equipment thoroughly.

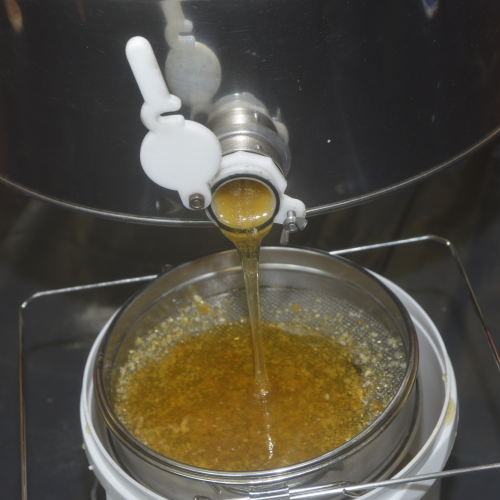

Sieving the honey

The liquid honey and debris from spinning is allowed to flow through multiple meshes and left to ‘settle’ for a few days in a warm area.

Tip: All equipment should be food grade e.g.stainless steel or plastic suitable for kitchen use. Use a coarse filter to remove wax particle etc, followed by a fine mesh of, say, 200 microns. These can be bought from equipment suppliers.

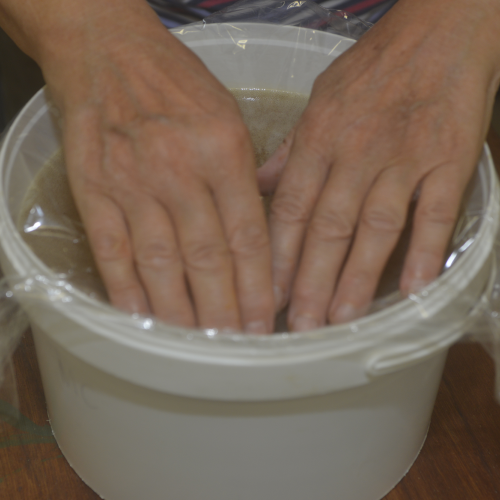

Use cling film as illustrated to remove froth from the surface. Just spread film over the honey surface and gently lift off.

The separated, filtered honey can be run into jars or stored in food grade tubs for future bottling.

Tip: Stored honey will eventually granulate and will need warming before bottling. Smaller tubs, e.g.15-lb, are easier to lift and handle and will melt more quickly causing less heat damage to the honey. Ideal storage temperature for honey in tubs or jars is 14°C

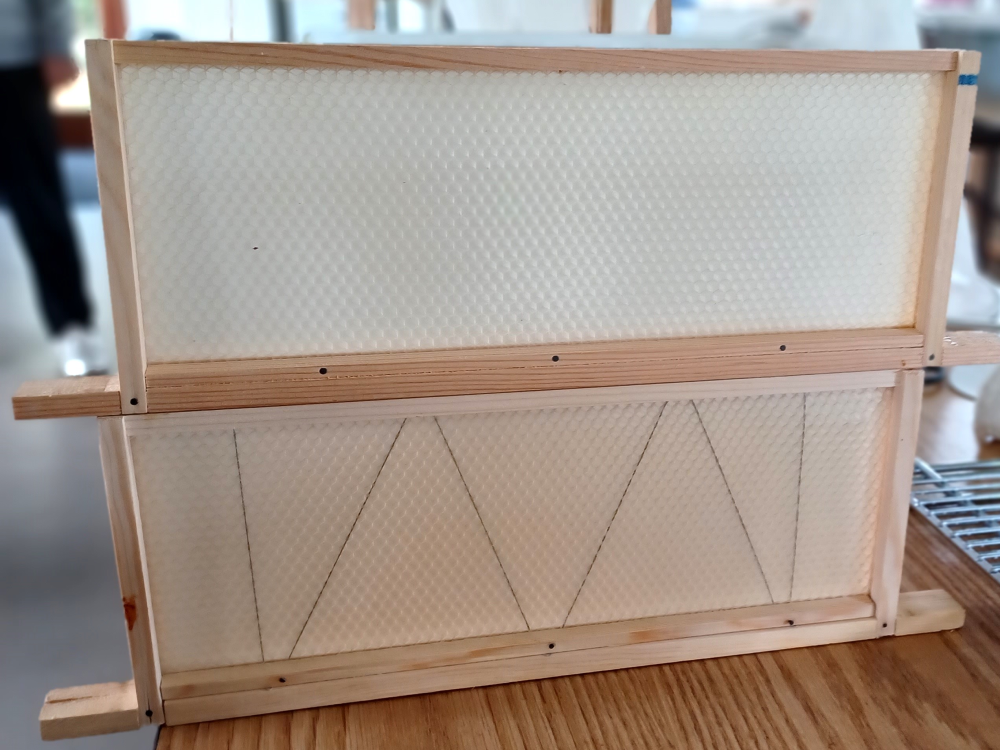

Cut Comb

This product is easy to prepare, does not need an extractor or settling tank, and commands a higher price than the equivalent weight of bottled honey.

Use special thin unwired comb foundation in supers. Needs a strong colony and a good honey flow.

Tip: Avoid the 1st super above the brood chamber as this will almost certainly contain some unwanted pollen. Method – cut blocks of comb with a comb cutter then place in a cut comb container. It doesn’t get much simpler than that.

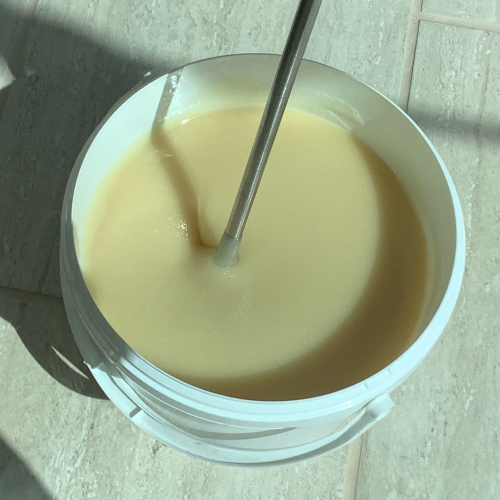

Soft set honey

Basically, control the crystallization process by stirring (see photos), or by adding approx 10% of finely grained OSR honey and mixing well. Bottle before it thickens then store in a cool place.

Wax cappings

What do you do with the wax cappings? Allow your cappings to drain in a covered container. The honey can be put through your sieves and the wet cappings can be put above the crown board for the bees to recycle the honey remnants.

Checking the moisture content of your honey

Legally, honey should be no more than 20% water content. Above this level there is every possibility that the honey will ferment and spoil. A refractometer will tell you the exact water content or you can rely on the ‘shake’ test. Take a frame with some uncapped cells, hold it horizontally over the hive and jerk it forwards and backwards a few times. If no drops of honey come out it is ripe enough to extract.

Tip: Always stir your buckets of honey top to bottom before storage. This will ensure all the honey is the same water content and helps to avoid fermentation.

Thanks Val and David. We hope these images help you to produce some first class products.

Literature

A good guide to processing honey would be Wally Shaw’s pamphlet Harvesting Honey, obtainable via Northern Bee Books or you can read online here.